A cnc machine uses computer numerical control to automate the movement of tools for shaping and cutting materials. You rely on cnc machines for precise, repeatable results in industries like automotive, aerospace, and woodworking. Over 65% of manufacturing companies in the United States use cnc, and the global market continues to expand rapidly.

A cnc machine uses computer numerical control to automate the movement of tools for shaping and cutting materials. You rely on cnc machines for precise, repeatable results in industries like automotive, aerospace, and woodworking. Over 65% of manufacturing companies in the United States use cnc, and the global market continues to expand rapidly.

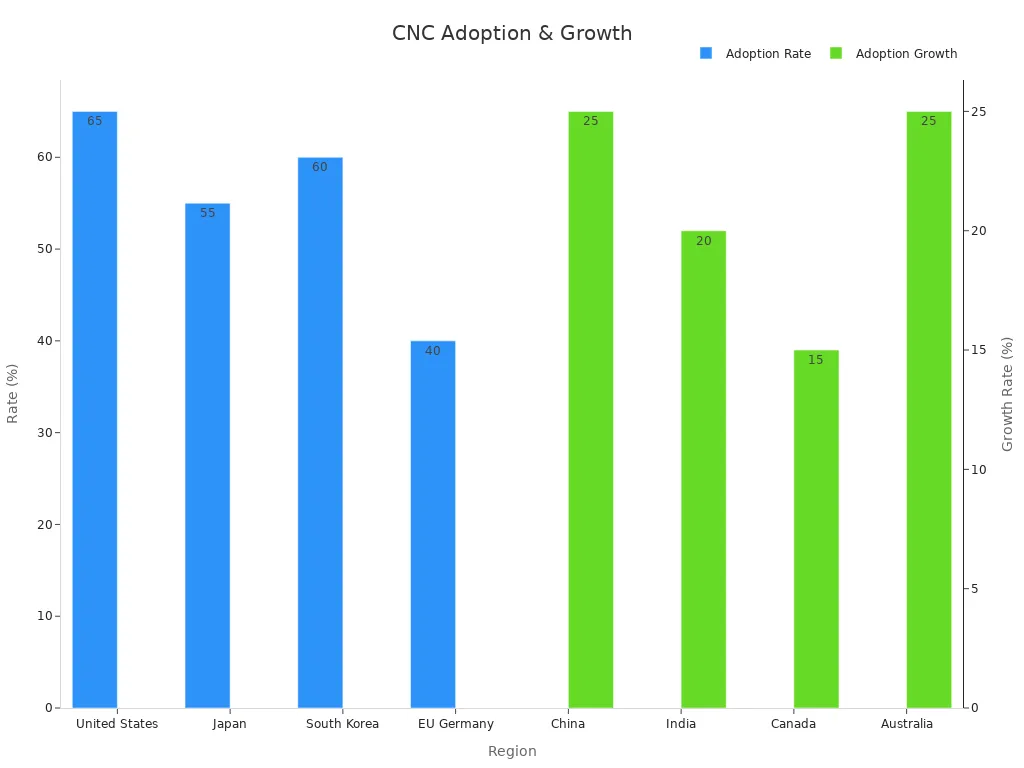

| Region / Country | Key Statistics on CNC Adoption and Market Growth |

|---|---|

| United States | - Manufacturing sector: 11.3% of GDP (2023)- 65%+ manufacturing companies use CNC- Automotive: 20% of CNC usage- Aerospace productivity up 15% (2019-2024)- 130,000 CNC operator jobs (2024), 8% job growth projected through 2030 |

| Europe (EU) | - Manufacturing: ~16% of GDP- Germany: 40% of factories with CNC (2023)- 18% increase in digital manufacturing investments (2020-2023)- EU exports 70%+ of high-precision machined products- European CNC market projected at $1.9B by 2025, CAGR 9.0% |

| Japan | - Manufacturing: ~20% of GDP- 55% of machine shops use CNC- 12% annual investment growth in automation (2018-2023)- CNC market projected $0.3B by 2025, CAGR 3.9% |

| China | - Largest global CNC producer (30%+ global output)- CNC adoption up 25% (2017-2022)- $1.5B government investment in smart manufacturing (2020-2023)- CNC supports 300,000+ manufacturing enterprises |

| India | - MSMEs contribute 30% manufacturing output- CNC adoption grew 20% (2019-2023)- $200M government modernization funding- CNC-machined exports up 15% annually (last 5 years) |

| Germany | - 40% of Europe's CNC production capacity- 10% rise in manufacturing export value (2019-2023)- 70%+ machine tool companies investing in CNC innovation- 22% growth in Industry 4.0 investments (2022) |

| South Korea | - CNC adoption rate >60%- 18% increase in CNC R&D investments (2020-2023)- CNC accounts for 25%+ of capital expenditure in precision engineering- CNC-machined exports up 12% annually (2018-2023) |

| Canada | - CNC sector ~5% of manufacturing output- 15% growth in CNC adoption (2018-2023)- $100M government investment in CNC training and modernization- 40,000+ skilled CNC jobs |

| Australia | - CNC used in 50%+ advanced manufacturing facilities- 7% contribution to manufacturing GDP (2023)- 20% increase in Industry 4.0 investments (2019-2023)- 25% growth in CNC adoption in SMEs (last 5 years) |

| Asia Pacific (Region) | - Expected 34.9% share of global CNC market revenue (2025)- Rapid industrialization and government support- Strong automotive, electronics, aerospace sectors |

| MEA Region | - Highest CAGR expected globally- Growth driven by infrastructure, oil & gas, aerospace- Government initiatives promoting automation |

| Global Market Trends | - Automotive & transportation: 28.3% market share (2025)- Integration with AI, Industry 4.0, IoT- Increasing demand for precision, complex machining- Growth in custom, low-volume manufacturing- Challenges: high costs, skilled labor shortages |

CNC machines use computer control to automate cutting and shaping, delivering high precision and repeatability in manufacturing.

You can operate CNC machines by creating digital designs and converting them into instructions that guide the machine’s movements.

Different types of CNC machines, like mills, lathes, routers, and panel saws, serve various production needs and materials.

Using CNC machines boosts efficiency by reducing downtime, lowering costs, and enabling continuous operation with minimal supervision.

CNC technology improves safety by automating tasks, reducing manual labor risks, and including protective features to prevent accidents.

What is CNC?

What is CNC?You encounter CNC, or computer numerical control, in almost every modern manufacturing environment. CNC refers to a system where computers direct the movement of machines and tools. This technology allows you to automate complex tasks that once required skilled manual labor. When you use a CNC machine, you rely on precise instructions written in programming languages like G-code and M-code. These codes tell the machine exactly how to move, cut, or shape materials.

CNC machining technology stands out because it delivers accuracy and repeatability. You can produce parts with tolerances as tight as 0.0002 inches. This level of precision is nearly impossible to achieve with manual methods. CNC machinists use their expertise to program and operate these machines, ensuring each part meets strict quality standards. As a CNC machinist, you benefit from the ability to create intricate designs and complex shapes across a wide range of materials, from metals to plastics.

Note: CNC machining does not require preproduction tooling. You can quickly modify designs and adapt to new requirements, making CNC ideal for industries like electronics, aerospace, and automotive.

Here is a table that clarifies some technical terms you may encounter in CNC machine programming and operation:

| Term | Definition |

|---|---|

| Poisson’s Ratio | Ratio of transverse strain to axial strain in a material under load. |

| Toughness | Ability of a material to absorb energy and deform without fracturing. |

| Hardening Modulus | Stress increase needed for continued plastic deformation. |

| Compressive Strength | Capacity to withstand compressive forces. |

| Wear Resistance | Ability to resist surface damage from friction or abrasion. |

| Resilience | Capacity to absorb energy elastically and recover. |

| Breakpoint | Stopping point in machining for inspection or tool change. |

| Eccentric | Offset component from rotation center. |

| Resistance | Opposition to flow of electricity or motion. |

| Torque | Rotational force applied to an axis. |

When you operate a CNC machine, you start by creating a digital design using CAD (computer-aided design) software. You then convert this design into a set of instructions using CAM (computer-aided manufacturing) software. These instructions, written in G-code and M-code, guide the CNC machine through each step of the process.

A typical CNC machine includes several key components:

Machine Tools: Sliding tables move along the X and Y axes, while spindles control the Z axis. Multi-axis control lets you perform complex machining tasks.

Feedback Systems: Encoders and sensors provide real-time data on position and speed. This feedback allows the machine to compensate for errors and maintain high precision.

Input Devices: You can transfer programs using keyboards, USB drives, wireless connections, or RS-232-C ports.

Automation Features: Automatic tool changers and multi-axis capabilities reduce manual intervention and boost efficiency.

Here is a table summarizing the operational principles and real-world validation of CNC machines:

| Aspect | Description / Validation |

|---|---|

| Machine Tools | Sliding tables (X, Y axes), spindles (Z axis), multi-axis control enable precise positioning and complex machining. |

| Feedback Systems | Encoders and sensors provide real-time data, enabling error compensation and high precision. |

| Input Devices | Keyboards, USB, wireless, and RS-232-C allow flexible program transfer for automated control. |

| Programming Languages | G-code controls movement; M-code manages auxiliary functions, automating complex tasks. |

| Automation Features | Automatic tool changers and multi-axis capabilities increase efficiency. |

| Operational Benefits | High precision, repeatability, reduced human error, and continuous operation improve quality and throughput. |

| Case Study: Automotive | CNC machining increased production, reduced defects, enabled 24/7 operation, and improved performance. |

| Case Study: Custom Guitars | CNC produced complex shapes on hardwood, showcasing intricate design capability. |

| Case Study: Hydraulic Cylinders | Production time cut by 50%, labor costs reduced by 30%, quality and reliability enhanced. |

| Case Study: Engine Components | Machining time reduced by 40%, throughput increased by 35%, inventory costs lowered. |

| Case Study: Structural Frames | Precision and repeatability improved, assembly time reduced, material utilization increased by 20%. |

You gain several advantages when you use CNC machines over manual machining:

CNC machines achieve precision with tolerances between 0.0002 to 0.0005 inches.

You maintain consistent quality across large production runs, reducing defects.

CNC machines operate continuously with minimal supervision, increasing efficiency.

Automation reduces labor costs and dependence on operator skill.

You can produce complex shapes and handle diverse materials.

Integration with CAD/CAM and IoT technologies enhances process optimization and predictive maintenance.

Despite higher initial costs, CNC machines offer long-term cost-effectiveness through reduced waste and labor savings.

Data generated during CNC operation supports ongoing performance improvements.

To keep your CNC machine running at peak performance, you must follow a regular maintenance schedule. This includes calibrating the machine, adjusting for backlash, aligning the spindle, and lubricating moving parts. You should also inspect bearings, check machine leveling, and replace worn components. Electrical and hydraulic systems require periodic checks to ensure safety and reliability. Regular maintenance ensures your CNC machine maintains accuracy within 0.0001 inches and extends its service life.

️ Tip: Real-world performance depends on factors like machine speed, acceleration, and tool change time. You should monitor these metrics to optimize your CNC machining process.

As a CNC machinist, you play a vital role in programming, operating, and maintaining these advanced machines. Your expertise ensures that each part meets exact specifications, whether you work in automotive, aerospace, or custom manufacturing. CNC machining continues to evolve, offering you new opportunities to improve efficiency, quality, and innovation in your field.

You encounter a wide range of cnc machines in modern manufacturing. Each type serves a unique purpose and fits specific production needs. While cnc mills, cnc lathes, routers, and panel saws are the most common, you also find specialized machines like laser cutters, plasma cutters, waterjets, and grinders. These machines vary by axis configuration, spindle type, and application, allowing you to select the best fit for your workflow.

Here is a table summarizing the global cnc machine market and its leading types:

| Aspect | Details |

|---|---|

| Market Size (2024) | USD 73.5 Billion |

| Market Size (2034) | USD 187.2 Billion |

| CAGR (2025-2034) | 9.8% |

| Leading CNC Machine Type | Lathe Machines (30% market share in 2024) |

| Other Machine Types | Milling Machines, Laser Machines, Welding Machines, Winding Machines, Grinders, Routers |

| End-User Segment Share | Industrial Applications (27% in 2024) |

| Regional Market Share | Asia Pacific (37% share, USD 27.20 Billion in 2024) |

| Top Companies | DMG Mori, Yamazaki Mazak, Okuma, Fanuc |

You use cnc mills to shape metal, plastic, and composite parts with high accuracy. These machines remove material from a workpiece using rotating cutting tools. Cnc mills operate on multiple axes, typically three to five, which lets you create complex shapes and features. You benefit from tight tolerances—down to 0.004 mm—and the ability to run production 24/7 with minimal supervision. Cnc mills excel at both prototyping and large-scale manufacturing. You can quickly switch between jobs, making them ideal for custom and batch production.

Cnc mills deliver high speed and precision, reducing human error.

You scale production easily, from single parts to thousands.

Real-time monitoring and predictive maintenance keep your cnc mills running efficiently.

Cnc lathes rotate a workpiece while cutting tools shape it into precise cylindrical forms. You rely on cnc lathes for parts like shafts, bushings, and threaded components. These machines follow computer-controlled instructions, which eliminates manual errors and maintains tolerances as tight as ±0.01 mm. Automated tool changers and part loaders boost productivity and reduce labor costs. You also gain a safer work environment, since cnc lathes feature enclosed workspaces and emergency stops.

Cnc lathes perform multiple operations in one setup, saving time.

You achieve uniform surface finishes and consistent quality.

Advanced turning centers add multi-axis machining for complex parts.

You turn to cnc routers when you need to cut, carve, or engrave materials like wood, plastics, composites, foam, or aluminum. Cnc routers stand out for their versatility across industries such as automotive, aerospace, medical, and packaging. You can produce custom parts, intricate designs, and even large panels with consistent quality. Multi-axis capabilities and fast tool changes help you increase efficiency and reduce production times.

Cnc routers handle a wide range of materials and job sizes.

You benefit from faster turnaround and long-term cost savings.

Integration with AI and IoT boosts automation and predictive maintenance.

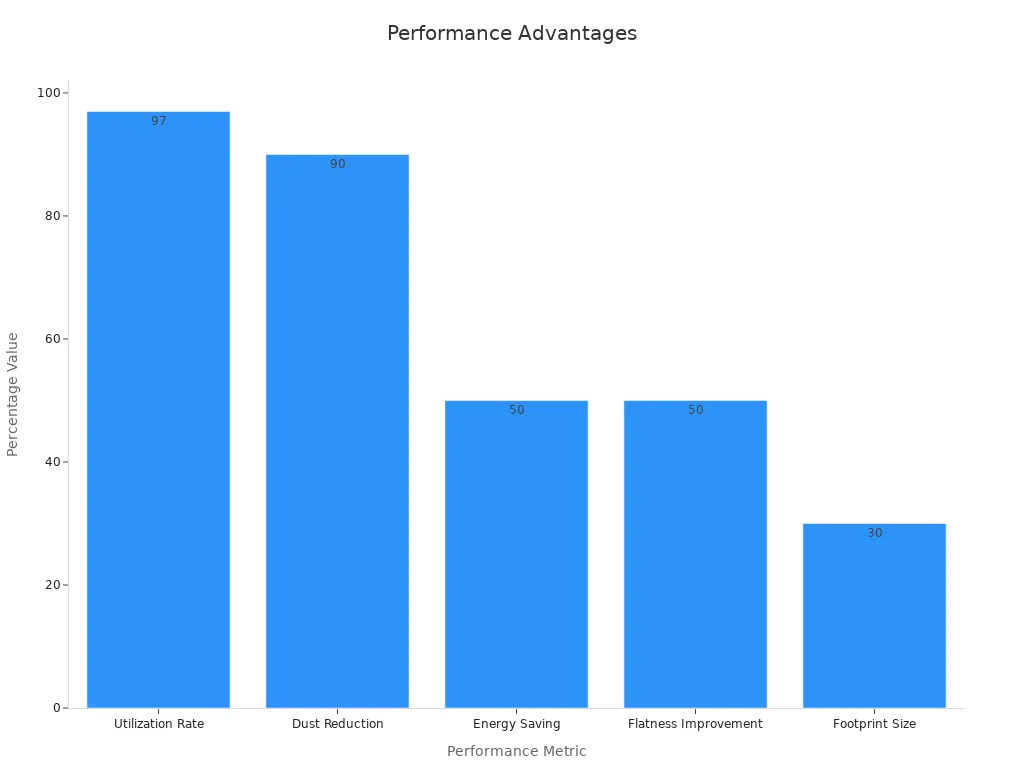

Cnc panel saws specialize in cutting large sheets or panels into precise sizes. You often use them in woodworking, furniture, and construction. Zhongyuan's Precision Panel Saw sets a new standard in this category. You achieve over 97% material utilization, 90% less dust, and a 50% improvement in flatness compared to conventional saws. The machine operates quietly, saves energy, and fits into smaller workshop spaces. You can cut ultra-thin slabs below 10 mm and enjoy a cleaner, safer workspace.

| Performance Metric | Zhongyuan's Precision Panel Saw Value | Comparison / Advantage Over Conventional Saws |

|---|---|---|

| Material Utilization Rate | Over 97% | 15-20% higher |

| Kerf Width | 0.4-0.7 mm | Narrow kerf improves material efficiency |

| Dust Generation Reduction | 90% less dust | Significantly cleaner operation |

| Noise Reduction | 40 dB reduction | Quieter operation |

| Energy Savings | 50% energy saving | More energy efficient |

| Minimum Slab Thickness | Below 10 mm | Enables ultra-thin cutting |

| Flatness Improvement | 50% better flatness | Higher precision |

| Wire Marks | Zero wire marks | Superior surface quality |

| Footprint Size | 30% smaller footprint | Saves workshop space |

Tip: You can choose from automatic, dust-free, portable, or sliding table models to match your production needs. Zhongyuan's cnc panel saws help you achieve reliable, efficient, and safe cutting for woodworking and beyond.

You gain significant efficiency when you use cnc machining in your production process. Automated systems allow cnc machines to run with minimal supervision, which means you can operate around the clock. Real-time monitoring software tracks machine performance and alerts you to downtime, helping you reduce unexpected stoppages by up to 40%. IoT sensors and AI analytics let you predict maintenance needs, so you avoid costly breakdowns and keep your workflow smooth.

| Efficiency Metric | Measurable Data / Result | Case Study Example |

|---|---|---|

| Downtime Reduction | Up to 40% reduction in downtime | Med device leader eliminated spreadsheets for scheduling |

| On-Time Delivery Improvement | Achieved 95% on-time delivery | Electrical device manufacturer improved customer responsiveness |

| Capacity Utilization Increase | Increased capacity utilization | Building materials company boosted capacity with better scheduling |

| Sales Growth | 10% sales increase through advanced planning | Reclaimed wood manufacturer improved sales by 10% |

You also benefit from optimized material usage, fewer production steps, and faster tool changes. These improvements help you lower operating costs and increase your output. With cnc, you can quickly adapt to new designs and deliver products on time.

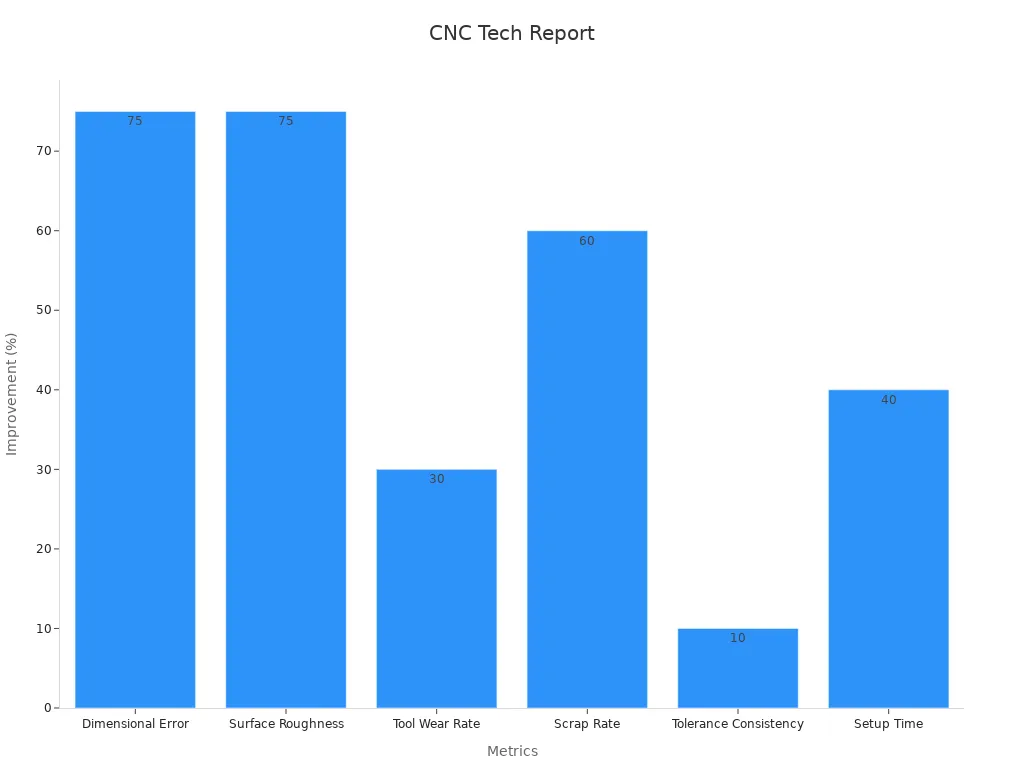

Cnc machining stands out for its unmatched precision. You achieve consistent part dimensions and tight tolerances, even on complex shapes. Advanced control systems and AI-driven adjustments reduce dimensional errors by up to 75%. You can maintain surface roughness as low as Ra 0.2 µm, which is essential for industries like aerospace and electronics.

You use control charts and statistical process control to monitor machining stability in real time. Regular calibration and error analysis help you keep accuracy high and scrap rates low. As a cnc machinist, you rely on these tools to deliver reliable results every time.

Cnc machining reduces production errors to nearly zero.

You minimize waste and lower costs.

You can produce prototypes and finished parts with the same high level of accuracy.

Cnc machines create a safer work environment for you and your team. Automated guarding systems and interlocked doors prevent access during operation, reducing the risk of injury. Safety sensors and programmable logic controllers monitor hazards and can stop machines instantly if needed.

| Safety Metric | Improvement Observed |

|---|---|

| Safety Compliance Rate | Increased from 85% to 98% within six months |

| Workplace Accident Rate | Reduced by 45% in the first year |

| Incident Response Time | Decreased by 50% |

| Data Accuracy | Improved by 60% |

You benefit from fewer accidents, faster response times, and better training through VR and AR simulations. As a cnc machinist, you work in an environment where technology actively protects you, allowing you to focus on quality and productivity.

You see cnc machines at the heart of modern manufacturing. These machines help you produce parts with high accuracy and speed. In large factories, cnc manufacturing boosts productivity by running equipment almost nonstop. You can track key metrics like Overall Equipment Effectiveness (OEE), First Pass Yield (FPY), and Capacity Utilization to measure how well your machines perform. For example, companies that monitor real-time data often increase machine utilization by up to 30%. This leads to lower costs, better supply chain management, and improved service levels.

Tip: Real-time monitoring of cnc machines helps you spot problems early and keep your production line running smoothly.

Cnc machines play a vital role in many industries. You use them to make engine parts in automotive plants, airfoils in aerospace, and bone screws in healthcare. In construction, cnc helps you create models and custom decor. The packaging industry relies on cnc to produce molds and components quickly.

| Industry / CNC Machine Type | Market Share / Price Range |

|---|---|

| Construction Industry | 5% market share |

| Furniture Industry | 3% market share |

| Packaging Industry | 1.5% market share |

| Industrial Sector | $28 billion, 25%+ of global market |

You benefit from cnc technology in woodworking when you need precise, repeatable cuts for furniture, cabinetry, or custom designs. Cnc routers and panel saws let you create intricate patterns and shapes that would be hard to achieve by hand. Zhongyuan's CNC woodworking panel saws stand out for their accuracy and efficiency. These machines help you cut wood, ABS boards, and other panels with smooth, clean edges. You save time on setup and enjoy safer, dust-free operation.

Cnc woodworking machines allow you to handle both small custom jobs and large production runs.

You can switch between different materials and designs with minimal downtime.

Advanced features, like automatic adjustments and safety guards, make your work easier and safer.

Note: With cnc woodworking, you achieve higher material utilization and better finishes, raising the quality of your projects.

You use cnc machines for rapid prototyping when you need to test new ideas quickly. Cnc lets you turn digital designs into real parts in just a few hours. This process saves you time and money because you do not need expensive tooling. You can create prototypes with tight tolerances, ensuring your samples match the final product.

Cnc prototyping reduces risk by letting you test designs before full production.

You achieve high accuracy and design fidelity, so your prototypes serve as reliable samples.

The process supports a wide range of materials and finishes, giving you flexibility.

Fast turnaround helps you speed up product development and get to market sooner.

Cnc machines also support short-run production, making them ideal for small batches. You can easily adjust your design and produce new versions without delay.

You gain many advantages when you use CNC machines in your production process. CNC technology boosts efficiency, improves precision, and creates a safer workplace. Studies show that:

You reduce musculoskeletal disorder risks by replacing manual tools.

Automated systems lower heavy lifting and injury risks.

About 76% of companies report higher productivity after adopting CNC.

CNC machining shapes the future of manufacturing. Consider how solutions like Zhongyuan's Precision Panel Saw can help you achieve better results.

Want to learn more? Explore industry reports and case studies on CNC advancements.

You can cut metals, plastics, wood, foam, and composites. CNC machines handle a wide range of materials, making them suitable for many industries. Always check your machine’s specifications before starting a new project.

You should perform basic maintenance daily. Schedule thorough inspections monthly. Regular cleaning, lubrication, and calibration keep your machine accurate and reliable.

Tip: Follow the manufacturer’s maintenance schedule for best results.

Yes, you can create custom parts and prototypes with CNC machines. Upload your digital design, and the machine will produce precise results. This flexibility supports rapid prototyping and small-batch production.

CNC machines include safety features like guards, sensors, and emergency stops. You must follow safety guidelines and wear protective equipment. Proper training ensures safe operation.

Note: Automated systems reduce the risk of workplace injuries.