Views: 0 Author: Site Editor Publish Time: 2025-07-01 Origin: Site

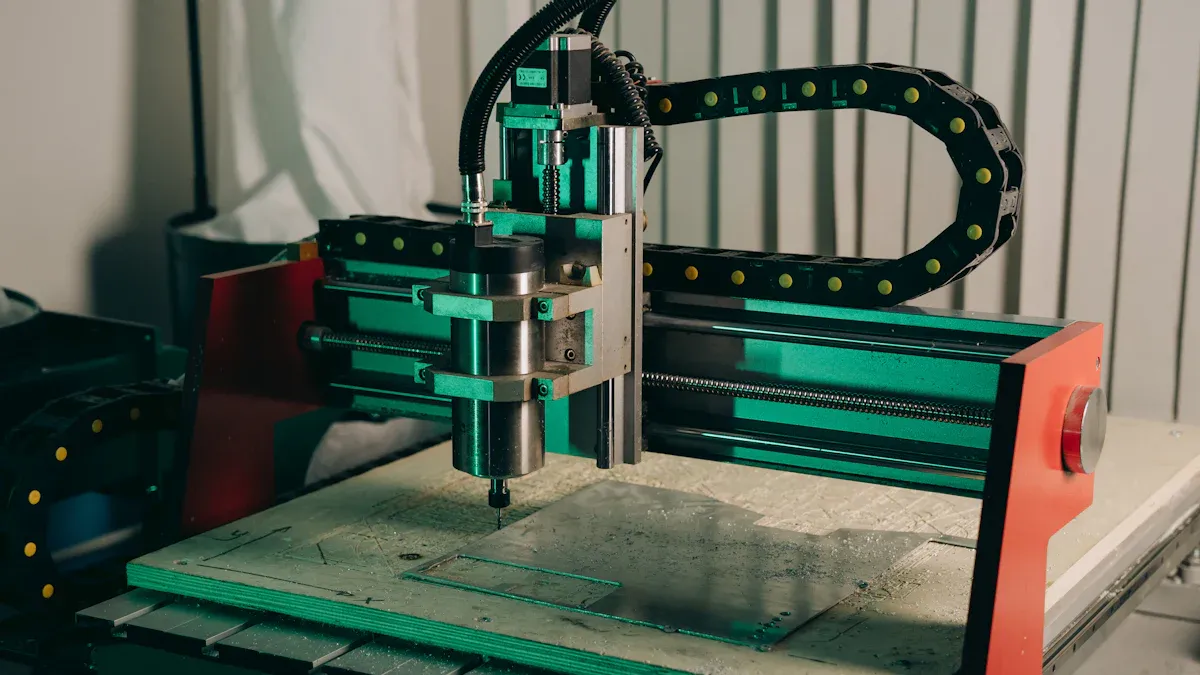

A CNC router machine uses computer numerical control to cut, carve, and engrave a wide range of materials. You can process wood, plastic, and metal with high precision using this type of router. CNC technology has transformed industries like woodworking and metalworking. The global market for CNC router machines reached USD 714.0 million in 2024, with strong growth projected.

Here’s a quick look at the current industry landscape:

| Metric/Segment | Details |

|---|---|

| Global Market Size (2024) | USD 714.0 million |

| Projected Market Size (2030) | USD 1,041.2 million |

| Largest Segment by Type | Moving-Table CNC Routers |

| Industry Applications | Woodworking, Metalworking, Plastic Fabrication, Others |

You will find leading brands like Shandong Zhongyuan Machinery Co., Ltd. offering advanced CNC wood router machines for professional results.

A CNC router machine uses computer control to cut and carve materials like wood, plastic, and metal with high precision.

The machine moves along three axes (X, Y, Z) guided by digital designs and G-code instructions for accurate shaping and engraving.

Key parts include the spindle, control system, tool changer, and feedback sensors that work together to ensure smooth and precise operation.

CNC routers offer automation, fast tool changes, and the ability to work with many materials, making them ideal for woodworking, signage, and industrial uses.

Choosing the right CNC router means considering size, material compatibility, automation features, and reliable after-sales support for long-term success.

When you use a CNC router machine, you rely on computer numerical control to automate the entire machining process. The system starts with a digital design, usually created in CAD (Computer-Aided Design) software. You then convert this design into a set of instructions called G-code. The CNC controller reads these instructions and sends precise commands to the motors and drives. This process ensures that the router follows the exact toolpaths needed for your project.

The motion control system acts as the brain of the machine. It coordinates the movement of the router along three main axes:

The X-axis moves the cutting tool left and right across the workpiece.

The Y-axis shifts the tool from front to back, adding depth and width control.

The Z-axis raises and lowers the tool, allowing for accurate depth during cutting, drilling, or engraving.

Sensors and feedback systems constantly monitor the position of the tool. These systems help you achieve high accuracy and smooth operation. The controller adjusts cutting speed, feed rate, and spindle speed to match the material and the complexity of your design. This level of automation and optimization is a core principle of CNC technology. You benefit from real-time monitoring, quality checks, and continuous improvement, which are all supported by international standards like ISO 14001 and ISO 45001.

Tip: G-code programming gives you full control over the router’s movements, making it possible to create complex shapes and detailed engravings with minimal manual intervention.

A CNC router machine consists of several key components that work together to deliver precision and efficiency:

Frame: The frame provides a stable foundation for the entire machine. A robust frame reduces vibration and ensures consistent results.

Spindle: The spindle serves as the main cutting component. It rotates at high speeds, allowing you to remove material quickly and accurately. Modern spindles offer high torque and integrated cooling systems, which help maintain performance during long jobs.

Worktable: The worktable holds your material in place. It often features clamps or vacuum systems to secure the workpiece, preventing movement during machining.

Control System: The control panel acts as the command center. It interprets G-code, manages axis movement, and controls spindle speed and tool changes. Advanced controllers, like those found in Shandong Zhongyuan Machinery Co., Ltd. machines, improve accuracy and repeatability.

Tool Changer: Automatic tool changers (ATC) allow the router to switch between different cutting tools without stopping the process. For example, the 1325 ATC CNC Wood Router Machine with Disc Tool Changer can change tools in seconds, reducing downtime and boosting productivity.

Drive Motors and Ball Screws: These components move the router along the X, Y, and Z axes. They convert electrical signals into precise mechanical motion.

Feedback Systems: Sensors and encoders provide real-time data on tool position. The closed-loop feedback mechanism corrects errors instantly, helping you maintain tight tolerances and reduce material waste.

Cutting Tools: You can use a variety of cutting tools, such as end mills, drills, and engraving bits. The choice depends on your material and the type of cut you need.

Coolant System: Some machines include a coolant system to keep the spindle and cutting tools at optimal temperatures, especially during heavy-duty operations.

| Component | Function | Benefit to You |

|---|---|---|

| Spindle | Rotates cutting tool at high speed | Enables precise and efficient cutting |

| Control System | Interprets instructions, manages operations | Ensures accuracy and repeatability |

| Tool Changer | Switches tools automatically | Reduces downtime, increases output |

| Feedback System | Monitors and corrects position in real time | Maintains quality, reduces errors |

| Worktable | Secures material | Prevents shifting, improves safety |

Advancements in component design have made modern CNC router machines more reliable and productive. For example, automated tool changers can reduce tool change times to just a few seconds. Real-time error compensation methods now achieve tolerances as tight as ±0.01 mm, which is essential for industries that demand high precision. Integration with CAD/CAM software lets you simulate tool paths before machining, further reducing errors and material waste.

When you choose a CNC router machine from a reputable manufacturer like Shandong Zhongyuan Machinery Co., Ltd., you gain access to advanced features such as disc tool changers, robust construction, and intelligent control systems. These innovations help you achieve superior results, whether you run a small workshop or a large-scale production facility.

You gain a significant advantage with a CNC router machine because of its advanced automation and precision. Automation allows you to program the router to follow exact toolpaths, eliminating manual errors and ensuring consistent results every time. The machine executes your designs with micrometer-level accuracy, thanks to features like servo motors, ball screws, and linear rails. These components provide smooth, backlash-free movement, which is critical for detailed engraving and cutting.

When you use a CNC wood router with a disc tool changer, such as the models from Shandong Zhongyuan Machinery Co., Ltd., you can switch between tools automatically. This feature reduces downtime and increases productivity, especially during complex projects that require multiple tool changes.

A sturdy frame made from steel or aluminum keeps vibrations low and maintains stability during operation. Feedback systems, including encoders and sensors, monitor the router’s position in real time and correct any deviations instantly. You benefit from standardized programming through CAD/CAM files, which ensures repeatability and high-quality output across production runs. Automated material handling and fixtures help you align parts consistently, reducing setup errors and improving safety.

Key features that enhance automation and precision:

Automatic tool changers (ATC)

Advanced control systems

Real-time error correction

Multi-axis capabilities for complex designs

A CNC router machine gives you the flexibility to work with a wide range of materials. You can cut, shape, and engrave wood, plastics, and composites with ease. The CNC router excels at processing softer materials and larger workpieces, making it ideal for furniture, cabinetry, and signage. You can also use it for plastics and specialized foams, which are common in electronics and aerospace applications.

The CNC Machining Material Selection Guide highlights how you can match the right material to your project by considering factors like moisture resistance, temperature tolerance, and mechanical strength. For example, rigid foam offers excellent moisture resistance and can handle temperatures from -100°F to 200°F, making it suitable for insulation components. Phenolics provide mechanical stability for demanding environments, while plastics serve a variety of roles across industries.

With a CNC router, you can:

Process wood, plastics, composites, and select foams

Achieve fast cutting speeds on large panels

Maintain tight tolerances for detailed work

Adapt to different project requirements with ease

You can rely on a modern router machine to deliver both versatility and precision, whether you run a small workshop or a large production facility.

You will find that woodworking stands as one of the main fields where cnc router machines excel. The CNC Router Market Report 2025 highlights woodworking as a primary application, with strong growth expected in this segment. When you use a cnc wood router, you can cut, carve, and engrave wood with high precision. This technology supports furniture manufacturing, cabinetry, and decorative woodwork. You can create intricate patterns, carve detailed motifs, and produce complex joinery such as dovetails and mortise and tenon joints. Many shops rely on a router machine to process panels, drill holes, and profile edges for cabinets and furniture. Whether you run a small workshop or manage a large production line, cnc routers help you maintain consistent quality and boost productivity.

Tip: CNC routers allow you to switch quickly between different tools and designs, making them ideal for both custom and mass-produced wood products.

You can use a cnc router to create signs, displays, and prototypes with sharp detail. The router cuts letters, logos, and graphics from wood, plastic, or composite materials. You can engrave intricate designs or produce raised lettering for commercial signage. In prototyping, cnc machines let you test new ideas and make rapid design changes. You can produce accurate models and patterns for industrial use. This flexibility helps you respond to customer needs and market trends quickly.

Common signage and prototyping applications:

Custom business signs

Exhibit and display fabrication

Pattern making for industrial parts

CNC router machines play a key role in large-scale industrial production. The cnc wood router machine market reached about USD 1.5 billion in 2024 and is projected to grow to USD 2.5 billion by 2033. This growth shows how industries value automation, precision, and customization. In factories, routers run continuously to cut, drill, and shape wood for furniture, cabinets, and architectural millwork. You can automate drilling, panel processing, and edge profiling, which improves efficiency and reduces labor costs. In small shops, you benefit from the flexibility to handle custom orders and specialized projects. CNC technology supports both environments by providing accuracy, repeatability, and integration with digital tools for monitoring and maintenance.

| Application Area | Industrial Application Details |

|---|---|

| Custom Furniture Manufacturing | CNC routers enable precise cutting of complicated joints and decorative patterns, improving furniture production efficiency and quality. |

| Cabinet Making and Installations | Automation of drilling and panel processing, accurate positioning for system holes, and organized manufacturing of cabinet faces and interiors. |

| Architectural Millwork | Production of complex moldings, panels, trims, and embellishments using custom router bits for detailed woodwork. |

| Pattern Making and Prototyping | Rapid design changes and creation of compact, complex patterns with sharp accuracy for industrial use. |

You can rely on a cnc router machine to deliver results in both high-volume factories and small, specialized workshops. The router adapts to your needs, whether you focus on efficiency or flexibility.

When you use a cnc router, you unlock a range of benefits that transform your workflow. The precision of cnc technology allows you to achieve tolerances as tight as ±0.001”, which means your joinery fits perfectly and you spend less time on rework. You can expect consistent results across large production runs, eliminating the variability that comes with manual cutting. High spindle speeds and controlled feed rates help you reduce chipping and tear-out, so your finishing work becomes much easier.

Key efficiency and accuracy benefits include:

Consistent tolerances for every part you produce

Reduced material waste through optimized nesting and toolpaths

Faster production with automated tool changers and barcode scanning

The ability for one operator to manage several cnc machines at once

Real-time monitoring and integration with ERP systems for better job tracking

Automatic tool changers (ATC) make your process even more efficient. You do not need to stop the router to switch tools, which reduces downtime and increases output. ATC systems also improve safety and minimize the risk of tool damage. These features let you focus on more complex projects and boost your productivity.

Note: Advanced cnc routers, like those from Shandong Zhongyuan Machinery Co., Ltd., combine automation, precision, and robust construction to deliver superior results in demanding environments.

Choosing the right cnc machine requires careful planning. You should start by defining your main application—woodworking, plastics, or signage—so you can match the machine’s specifications to your needs. Consider the size and capacity of the router, as larger machines cost more but handle bigger projects. Look for features like spindle power, axis configuration, and automation options that fit your workflow.

Important factors to consider:

Machine size and worktable dimensions

Material compatibility and spindle type

Required accuracy and automation features

Supplier reliability and brand reputation

After-sales support, including training and spare parts availability

Warranty coverage and technical assistance

A reputable brand, such as Shandong Zhongyuan Machinery Co., Ltd., offers not only high-quality cnc routers but also strong after-sales service. This support reduces downtime and gives you peace of mind throughout the machine’s life cycle.

| Factor | Why It Matters |

|---|---|

| Machine Size | Affects project capacity and overall cost |

| After-Sales Support | Reduces downtime and long-term expenses |

| Brand Reputation | Ensures quality and reliable performance |

| Automation Features | Boosts productivity and efficiency |

Tip: Always calculate the total cost of ownership, including shipping, installation, and maintenance, before making your final decision.

You now understand that a cnc router combines computer control with advanced features to deliver precise, automated machining. As you consider investing in a cnc router, remember that market trends show growing demand for customization and automation. Experts highlight the need to evaluate cnc features, such as multi-axis machining and safety systems, to match your production goals. Automation not only improves efficiency but also reduces workplace injuries. Explore reputable brands to find a cnc router that fits your needs and supports future growth.

You use a CNC router machine for cutting wood, plastics, and soft materials. A CNC milling machine works best for metals and harder materials. Both use computer numerical control, but routers operate at higher speeds and handle larger workpieces.

Yes, you can use a CNC wood router to cut plastics, composites, and some soft metals. Always check the machine’s specifications and select the right cutting tools for each material.

An automatic tool changer lets your router machine switch tools quickly during jobs. You save time and reduce manual intervention. This feature boosts productivity, especially when you work on complex projects with multiple tool changes.

You should check the machine size, spindle power, and automation features. Consider after-sales support and the reputation of the manufacturer. Make sure the router matches your main application, whether you need a cutting machine for wood or other materials.

You can learn computer numerical control basics with practice. Most CNC router machines use user-friendly software. Many manufacturers offer training and support, making it easier for you to operate the machine and create precise designs.