Views: 0 Author: Site Editor Publish Time: 2025-06-30 Origin: Site

When you explore the world of CNC machines, you will encounter five main types: CNC milling machines, CNC lathe machines, CNC routers, CNC laser cutting machines, and CNC plasma cutting machines. Each type of CNC machine offers unique capabilities for different industries and applications. Understanding the types of CNC machines helps you select the right equipment for your specific needs. For woodworking professionals, innovative solutions from companies such as Shandong Zhongyuan Machinery Co., Ltd. stand out in the market.

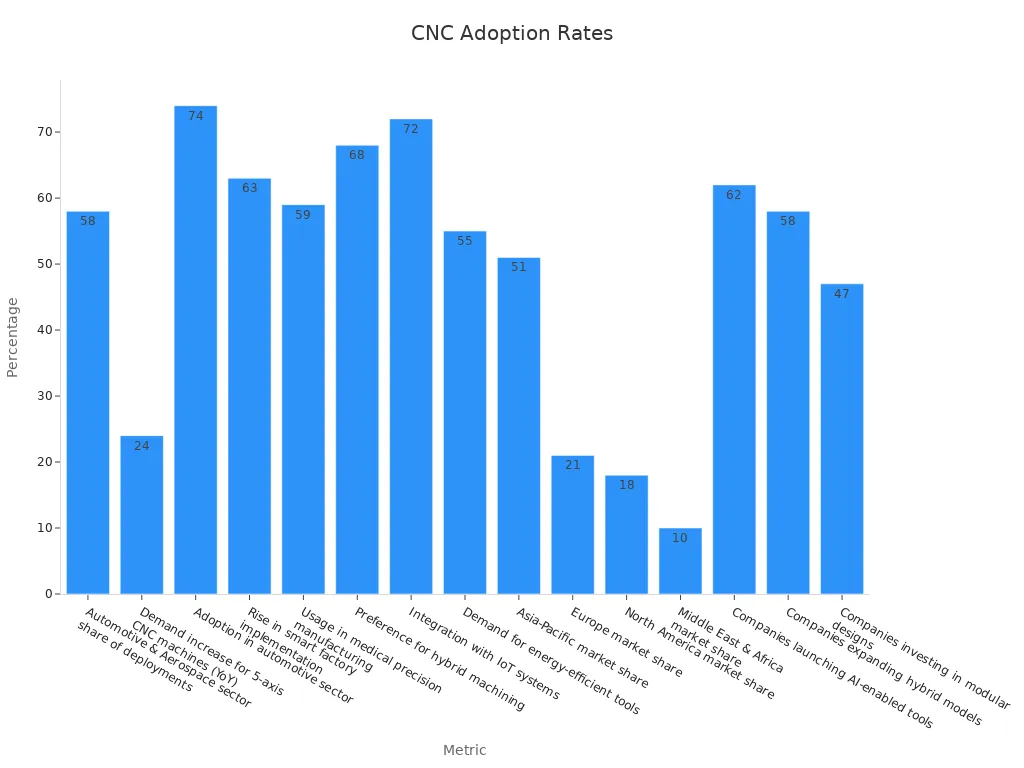

The global CNC machinery market reached USD 87.46 billion in 2024, with Asia-Pacific leading in adoption rates.

CNC milling machines currently dominate by revenue, while laser machines show strong growth potential.

There are five main types of CNC machines: milling, lathe, router, laser cutting, and plasma cutting, each designed for specific materials and tasks.

CNC milling machines excel at shaping hard metals with high precision, while CNC routers are best for woodworking and softer materials with faster production.

CNC laser cutting machines provide clean, precise cuts for delicate materials, and plasma cutters handle thick metals quickly and affordably.

Choosing the right CNC machine depends on your material, desired precision, and production needs to maximize efficiency and quality.

Advanced CNC machines offer automation, reduce errors, and lower costs, helping businesses improve productivity and stay competitive.

When you explore the different types of CNC machines, you will find that each one serves a unique purpose in modern manufacturing. The five most common types of CNC machines include:

CNC Milling Machine

CNC Lathe Machine

CNC Router

CNC Laser Cutting Machine

CNC Plasma Cutting Machine

These machines have transformed industries by offering precision, speed, and automation. You can see their impact in sectors such as automotive, aerospace, woodworking, and metal fabrication. According to the MarketsandMarkets report, companies use a combination of secondary and primary research to analyze the market share and technical specifications of each CNC machine type. This approach helps manufacturers and buyers understand which machine best fits their needs.

Tip: Choosing the right CNC machine depends on your material, desired finish, and production volume.

CNC milling machines use rotating multi-axis cutting tools to remove material from a workpiece. You can create complex shapes, flat surfaces, and intricate details with high precision. These machines support both horizontal and vertical configurations, making them versatile for various tasks. Industries rely on CNC milling machines for producing engine blocks, molds, and custom parts. You will often find them in automotive, aerospace, and general manufacturing facilities.

CNC milling machines excel at cutting, drilling, and slotting hard metals.

They operate using G-code, which allows for precise control over movement and speed.

Many models offer 3 to 5-axis capabilities, enabling you to produce complex geometries.

CNC lathe machines rotate the workpiece against a stationary cutting tool. You can use them to create cylindrical, conical, or flat products. These machines perform operations such as cutting, sanding, facing, drilling, and threading. CNC lathes are essential for manufacturing automotive parts, musical instruments, and furniture components.

CNC lathes handle metals, plastics, and composites.

You can achieve high accuracy when producing shafts, bushings, and other round parts.

Automation features help you increase throughput and reduce manual labor.

CNC routers are especially important in woodworking and sign making. You can use a CNC router to cut, carve, and engrave soft materials like wood, plastics, and composites. These machines operate faster than milling machines but offer slightly less precision, making them ideal for large-scale projects.

Shandong Zhongyuan Machinery Co., Ltd. stands out as a leading provider of advanced CNC routers and specialized woodworking CNC machines. Their CNC Wood Door Locking Machine with Drilling & Slotting streamlines door manufacturing by integrating drilling and slotting functions. This innovation ensures efficient, accurate, and high-quality production for woodworking professionals.

CNC routers support complex designs and large workpieces.

You can use them for cabinetry, furniture, prototyping, and signage.

Automation and user-friendly controls make them accessible for both small workshops and large factories.

CNC laser cutting machines use a focused laser beam to cut or engrave materials. You can achieve high precision and clean edges, especially on delicate or thin materials. These machines are popular in industries that require intricate designs and fine details, such as aerospace, medical equipment, and automotive manufacturing.

CNC laser machines excel at engraving, rust removal, and welding.

You can use them on metals, plastics, glass, and ceramics.

The non-contact process reduces material waste and ensures a smooth finish.

CNC plasma cutting machines use a plasma torch to cut electrically conductive materials quickly and efficiently. You can rely on these machines for thick metals, making them common in fabrication shops and the automotive industry.

CNC plasma cutters handle steel, aluminum, brass, and copper.

The process uses an ionized gas stream to achieve fast, precise cuts.

You can benefit from their speed and ability to cut complex shapes in heavy-duty applications.

Note: Case studies from Methods Machine Tools show that companies have reduced costs by up to 70% and tripled throughput by adopting advanced CNC machines, including plasma and milling models.

When you understand the types of CNC machines and their applications, you can make informed decisions for your business. CNC routers, in particular, offer significant advantages for woodworking professionals. Shandong Zhongyuan Machinery Co., Ltd. provides innovative solutions that help you achieve efficiency, precision, and quality in your production process.

Description

DescriptionYou use a CNC milling machine to shape solid materials like metal, plastic, or wood. This machine operates with computer-controlled precision, guiding a rotating cutting tool along multiple axes. You can select from a range of tooling options, such as end mills, reamers, and drill bits. Tool materials include high-speed steel, carbide, and even diamond, each designed for specific tasks and materials. Many modern CNC milling machines feature vacuum hold down systems. These systems use vacuum pumps and gauges to keep your workpiece stable, ensuring accuracy during every operation.

CNC milling machines perform a wide variety of tasks. You can cut, drill, slot, and contour complex shapes with ease. The machine reads digital instructions and moves the cutting tool exactly where you need it. You can switch between different tools for profiling, hole creation, or precise sizing. Advanced guides highlight the importance of tool geometry and coatings, which help you optimize performance for each job. In advanced manufacturing, studies show that actual machine performance depends on more than just technical specifications. You need to consider accuracy, cycle time, tool wear, and surface finish when choosing a machine for your shop.

You will find CNC milling machines in many industries. Aerospace companies use them to create engine parts and structural components. Automotive manufacturers rely on them for custom parts and molds. You can also use these machines in electronics, medical device production, and woodworking. Their ability to automate complex tasks helps you produce high-quality parts quickly and efficiently. When you need to customize products or respond to changing market demands, CNC machining gives you the flexibility to adapt.

CNC milling machines offer several key advantages over traditional methods. You gain higher precision and repeatability, reducing errors and rework costs. Automated controls let you produce complex parts faster and with less reliance on operator skill. Compared to manual milling, CNC machining provides better surface finishes and longer tool life, especially when using climb milling techniques. You also benefit from improved efficiency and lower operational costs for high-volume production. A comparison of mill-turn CNC machining and traditional methods shows that you can achieve tighter tolerances, faster production, and greater versatility with modern CNC milling machines.

Tip: Regularly monitor your vacuum hold down system. Maintaining proper vacuum pressure ensures part stability and consistent results.

You use a CNC lathe machine to shape materials into precise cylindrical forms. This machine rotates your workpiece while a computer-controlled cutting tool removes material. You can program the machine to follow exact paths, ensuring each part meets strict specifications. Modern CNC lathes and turning machines feature advanced control systems, multiple axes, and robust build quality. These features help you achieve high accuracy and repeatability, even with complex designs or large components.

Tip: Real-time monitoring and smart sensors in new models help you catch issues early, reducing downtime and improving productivity.

With a CNC lathe machine, you perform turning operations that create shafts, bushings, threads, and cams. The machine allows you to control spindle speed, feed rate, and tool movement with precision. You can switch between different tools quickly, making it easy to handle various projects. Automated tool changes and CAD/CAM compatibility streamline your workflow. Metrology tools, such as coordinate measuring machines, help you verify part accuracy and maintain quality standards.

You achieve micron-level precision, which is essential for industries like aerospace and automotive.

Automation reduces manual adjustments and human error, increasing output and consistency.

You can produce both simple and intricate parts with minimal setup time.

You find CNC lathes and turning machines in many industries. In automotive manufacturing, you use them to produce camshafts, crankshafts, and other symmetrical engine components. Aerospace companies rely on these machines for turbine blades, compressor discs, and hydraulic manifolds. The ability to handle a wide range of materials, from aluminum to titanium, makes CNC machining vital for high-performance parts. You also see these machines in medical device production and general metalworking.

| Application Area | Example Components | Importance |

|---|---|---|

| Automotive | Camshafts, crankshafts | High precision, mass production |

| Aerospace | Turbine blades, manifolds | Tight tolerances, lightweight durability |

| Medical Devices | Surgical tools | Consistent quality, intricate shapes |

You gain several advantages when you use CNC lathes and turning machines. These machines deliver tolerances as tight as 0.001 mm, far surpassing conventional lathes. Automated operation lets you run production 24/7 with minimal supervision, reducing labor costs by up to 50%. You increase overall production by 25-40% and cut production time by about 30%. Consistent quality across large runs ensures every part meets your standards. CNC machining also reduces material waste and supports Industry 4.0 integration for smarter manufacturing.

Note: Choosing the right machine with the right features helps you balance cost, efficiency, and long-term value.

You use a CNC router to cut, carve, and engrave materials like wood, plastic, and composites. This machine operates with computer-controlled precision, guiding a spindle along multiple axes to create detailed shapes and patterns. CNC router machines have evolved from basic numerical control systems to advanced equipment that supports complex designs and large workpieces. You benefit from features such as intelligent speed control, robust mechanical structures, and user-friendly software, which make these machines reliable and efficient for modern production.

A CNC router machine performs a wide range of tasks. You can program it to cut intricate patterns, drill holes, and engrave logos or text. The machine reads your digital design, secures the material, and selects the right cutting bit for the job. Intelligent features like cross-border protection and advanced prediction algorithms help you avoid errors and maintain high accuracy. You can also resume carving from a breakpoint, which ensures you do not lose progress if the process stops unexpectedly.

You will find CNC routers essential in woodworking and sign making. In woodworking, you use them to produce cabinets, furniture, and decorative panels with complex joinery and curved surfaces. For sign making, you rely on their ability to cut acrylic, metal, and wood into detailed shapes and letters. Shandong Zhongyuan Machinery Co., Ltd. offers advanced CNC router solutions, such as the CNC Wood Door Locking Machine with Drilling & Slotting. This machine streamlines door manufacturing by integrating drilling and slotting, improving efficiency and accuracy for workshops and factories. Case studies show that CNC routers help you reduce production costs, minimize material waste, and enable mass customization, especially when combined with digital design tools.

CNC routers offer several advantages over other CNC machining equipment for woodworking. You achieve faster production speeds, larger work areas, and cost-effective operation. The machines provide high precision and repeatability, which ensures consistent quality across batches. Compared to CNC mills, CNC routers handle softer materials more efficiently and support larger projects. You also benefit from features like dust collection systems, which keep your workspace clean and safe. These advantages make CNC router machines the preferred choice for woodworking professionals seeking flexibility, speed, and reliable results.

You use a cnc laser cutting machine to cut and engrave materials with a focused, high-energy laser beam. This process does not require direct contact with the material. The machine melts or vaporizes the surface, and assist gases like oxygen or nitrogen help remove the molten or vaporized material. You can choose from different types of lasers, such as CO2 for non-metals or fiber lasers for metals. Modern cnc laser cutting machines come in various configurations, including flatbed models for sheets and 3D machines for complex shapes. You benefit from high precision and the ability to handle both metals and non-metals.

A cnc laser cutting machine performs several key functions in manufacturing. You can use it to cut, engrave, or mark a wide range of materials, including steel, aluminum, plastics, wood, and ceramics. The machine reads your digital design and follows exact paths, ensuring accuracy and repeatability. You can adjust the laser power and speed to optimize the process for different materials and thicknesses. Advanced models allow you to monitor the cutting process in real time, which helps you maintain quality and reduce waste. Studies show that increasing cutting speed can improve cut quality, especially when working with advanced composites.

Tip: For best results, select the right assist gas and laser type based on your material and desired finish.

You will find cnc laser cutting machines in many industries. In aerospace, you use them to create engine components and intricate interiors. Automotive manufacturers rely on them for engine parts, body panels, and transmission components. Medical device companies use laser cutting for custom implants and surgical tools. Electronics manufacturers depend on precise laser cutting for circuit boards and tiny components. You also see these machines in architectural design, metal fabrication, woodworking, jewelry making, and rapid prototyping. User testimonials highlight the reliability, clean cuts, and easy integration of these machines into production lines.

Aerospace: Engine parts, interiors

Automotive: Body panels, gears

Medical: Implants, surgical tools

Electronics: Circuit boards, connectors

Architecture: Decorative panels, facades

Woodworking: Furniture, intricate designs

You gain several advantages when you use a cnc laser cutting machine. The process offers high precision and speed, with cutting rates up to 100 meters per minute. You achieve clean edges and tight tolerances, often with little or no post-processing required. Laser cutting produces a small kerf width, which means you use more of your material and reduce waste by up to 30% compared to other methods. The non-contact process minimizes material contamination and tool wear. Compared to plasma or mechanical cutting, laser cutting gives you better accuracy, less heat deformation, and greater flexibility for complex shapes. Fiber lasers also offer lower operating costs and faster speeds, especially for thin metals. You can easily integrate these machines with other CNC equipment for smart manufacturing.

Note: Laser cutting is ideal when you need high-quality, repeatable results and want to maximize material usage.

You use a cnc plasma cutting machine to cut through electrically conductive metals with speed and precision. The machine creates a high-temperature plasma arc by ionizing gases such as compressed air or oxygen. This arc melts the metal, and the force of the gas blows away the molten material, leaving a clean cut. Automated CNC controls guide the plasma torch along programmed paths, allowing you to produce both intricate and standardized shapes. Modern cnc plasma cutters come in various forms, including portable units for fieldwork and large gantry systems for industrial fabrication. Recent advancements include smart control systems, improved plasma sources, and robotic integration, which boost productivity and reliability.

Cnc plasma cutters perform several key tasks in metalworking. You can use them to cut, pierce, and bevel metals like steel, stainless steel, aluminum, copper, and brass. The machines handle both thin sheets and thick plates, depending on their power and arc stability. You benefit from features such as automatic controllers, real-time diagnostics, and software compatibility, which make setup and operation straightforward. Field reports highlight the importance of pre-operational checks, continuous monitoring, and post-cutting procedures like slag removal to ensure safety and quality. Industrial models use robust servo motors and advanced CNC units, supporting continuous operation and high-volume production.

Tip: Always inspect your cnc plasma cutting machine before use. Regular maintenance ensures consistent performance and extends machine life.

You find cnc plasma cutters in many industries. They play a vital role in automotive repair, fabrication shops, salvage operations, and industrial construction. You also see them in shipyards, manufacturing plants, and trade schools. Common uses include:

Fabrication of custom metal parts

Maintenance and repair of heavy equipment

Cutting and shaping steel beams for construction

Salvage and scrapping of old machinery

Training students in advanced metalworking techniques

These machines support a wide range of projects, from small repairs to large-scale industrial builds.

Cnc plasma cutters offer several advantages over other cutting methods. You achieve faster cutting speeds, especially for materials up to 50 mm thick, without the need for preheating. The machines cut a wide variety of conductive metals, making them versatile for different jobs. CNC automation ensures high precision, consistent results, and minimal material distortion. You also benefit from lower initial and operating costs, particularly when working with thicker materials. The table below highlights how cnc plasma cutting machines compare to other methods:

| Aspect | CNC Plasma Cutting Advantages | Compared Methods (Laser, Oxy-Fuel) |

|---|---|---|

| Speed | Rapid cutting, no preheating needed | Oxy-fuel slower; laser slower on thick materials |

| Material Compatibility | Cuts many conductive metals, thick and thin | Oxy-fuel for ferrous metals; laser best for thin materials |

| Precision | High with CNC automation, minimal distortion | Laser higher for thin; oxy-fuel less precise |

| Cost-effectiveness | Affordable for thick materials | Laser more expensive; oxy-fuel ongoing fuel costs |

| Versatility | Handles diverse metals and thicknesses | Laser limited to thin; oxy-fuel limited in metal types |

You gain improved safety and productivity, as automation reduces exposure to hazardous conditions and repetitive tasks. Studies show that optimizing cutting parameters can reduce costs by up to 28% and increase speed by 65%. These benefits make cnc plasma cutters a top choice for heavy-duty industrial applications.

When you compare the five most common cnc machines, you notice clear differences in their design, function, and application. Each cnc machine type offers unique advantages for specific tasks. The table below summarizes the main distinctions:

| CNC Machine Type | Main Uses | Best Materials | Precision Level | Typical Cost Range | Key Advantages |

|---|---|---|---|---|---|

| CNC Milling Machine | Complex parts, molds, prototypes | Metals, plastics, wood | High | $25,000–$100,000 | Versatile, precise, repeatable |

| CNC Lathe Machine | Cylindrical parts, shafts | Metals, plastics | Very High | $15,000–$150,000+ | Fast, accurate, automated |

| CNC Router | Woodworking, signage, panels | Wood, plastics, soft metals | Medium-High | $15,000–$80,000 | Large work area, fast, flexible |

| CNC Laser Cutting Machine | Intricate cuts, engraving | Sheet metal, plastics, wood | Extremely High | $20,000–$250,000+ | Clean edges, minimal waste |

| CNC Plasma Cutting Machine | Heavy metal fabrication | Steel, aluminum, copper | Medium | $20,000–$100,000 | Fast for thick metals, affordable |

Tip: The number of axes in a cnc machine affects its complexity and the shapes you can produce. More axes mean greater flexibility but also higher cost and skill requirements.

You should choose your cnc machines based on your material, desired precision, and production scale. Here are some best-use scenarios:

Use a cnc milling machine for detailed metal parts in aerospace or automotive projects.

Select a cnc lathe machine when you need high-precision cylindrical components like shafts or bushings.

Choose a cnc router for woodworking, cabinetry, or sign making, especially if you work with large panels or need fast turnaround.

Opt for a cnc laser cutting machine for intricate designs, electronics, or projects that require clean, precise edges.

Pick a cnc plasma cutting machine for heavy-duty metal fabrication, such as construction beams or industrial equipment.

You gain the most value when you match the right cnc machine to your specific job. This approach helps you maximize efficiency, control costs, and achieve the best results for your business.

Understanding the five main types of CNC machines empowers you to make informed decisions for your business. The table below highlights key factors, such as price range, material suitability, and machine precision, that influence your choice:

| Aspect | Details |

|---|---|

| Price Range | Hobbyist CNC machines under $1000; commercial machines from ~$18,000 to over $1 million |

| Material Suitability | Routers for soft materials (wood, foam, plastic); Mills for hard metals (aluminum, steel, titanium) |

| Machine Precision | Mills can cut within thousandths of an inch; routers less accurate |

| Machine Size & Auxiliary Needs | Some machines (e.g., laser cutters) require large space and additional equipment like air compressors and dust collectors |

| Downtime Costs | Automotive industry loses ~$22,000 per minute of unplanned downtime; average manufacturer faces 800 hours/year downtime |

| Maintenance Impact | Predictive and preventative maintenance improves uptime and productivity |

You see rapid growth in the CNC market, driven by technological advancements and demand for customization. Specialized providers like Shandong Zhongyuan Machinery Co., Ltd. deliver advanced solutions for woodworking, including cnc electrical discharge machines and cnc waterjet cutting machine options. As you evaluate your needs, consider how features like precision, automation, and integrated support can help you stay competitive.

| Aspect | Evidence |

|---|---|

| Market Size & Growth | CNC machine market projected to grow from USD 67,485 million in 2024 to USD 146,776.58 million by 2032, CAGR 10.20% |

| Industry 4.0 & Smart Manufacturing | Integration of IoT, AI, machine learning, and big data analytics enabling real-time monitoring, predictive maintenance, and process optimization |

| Leading Providers | Yamazaki Mazak Corporation, FANUC America Corporation, Schuler AG investing heavily in R&D and expanding product lines for advanced CNC solutions |

| Automotive Industry Impact | Rapid development and customization needs driving demand; 36% of consumers willing to pay more for personalized products (source: Deloitte) |

| Technological Advancements | Adoption of digital twin technology, hybrid manufacturing, energy-efficient machines supporting specialized CNC solutions |

| Challenges | Skilled labor shortages and complex maintenance highlight need for advanced, user-friendly integrated solutions |

| Government & Sustainability | Initiatives and sustainability trends reinforcing market growth and strategic value of specialized CNC solutions |

Tip: Evaluate both cnc electrical discharge machine and cnc water jet cutters for specialized applications to maximize productivity and quality.

You can process metals, plastics, wood, foam, and composites with CNC machines. Some machines, like cnc waterjet cutting machine and cnc electrical discharge machines, handle hard metals and specialized materials with high precision.

You should consider your material type, production volume, and required precision. For woodworking, a CNC router works well. For metals, you might select a cnc electrical discharge machine or cnc water jet cutters.

You use CNC routers for softer materials and larger panels. CNC mills handle harder metals and offer higher precision for complex parts. Your choice depends on your project requirements.

Yes, you can create custom designs by uploading digital files. The machine follows your programmed path, producing unique shapes and patterns with accuracy.

You can use compact CNC machines in small workshops. Many models offer user-friendly controls and require minimal space. Even advanced options like cnc waterjet cutting machine fit into modern, efficient workspaces.