Views: 0 Author: Site Editor Publish Time: 2025-06-25 Origin: Site

Image Source: pexels

An atc cnc router is a machine controlled by a computer. It uses new technology to cut wood and other things. The automatic tool changer lets the cnc router change tools fast. This saves time and means people do less work by hand. Many factories use a woodworking cnc router. It helps them work faster and with more accuracy. The cnc router machine from Shandong Zhongyuan Machinery Co., Ltd. is special in this field. Their 1325 ATC CNC Wood Router Machine with Disc Tool Changer is a good example. It shows how a cnc router can make woodworking better and more efficient. People use a cnc router for drilling, cutting, and engraving. A woodworking cnc router gives modern workshops more speed and better results.

ATC CNC routers can change tools by themselves very quickly. This saves time and lets the machine work longer without stopping.

These routers can cut wood, plastic, metal, and stone. They do this with high accuracy. This makes them good for furniture, signs, and detailed designs.

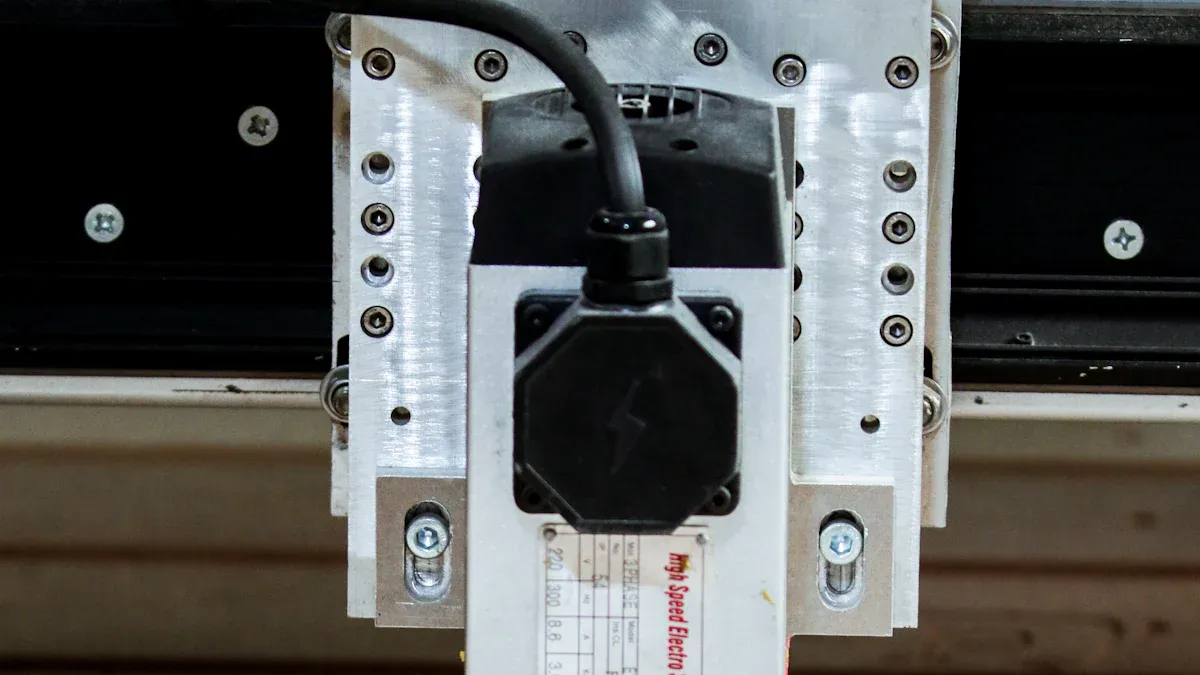

The Zhongyuan 1325 ATC CNC Wood Router Machine has strong features. It has a vacuum table, an air-cooled spindle, and dust collection. These help keep the work neat and smooth.

Using an ATC CNC router helps businesses work faster. It also helps lower mistakes and lets people do harder jobs with less work.

Picking the right CNC router depends on what you need, what materials you use, and your budget. Good care and help from the supplier keep the machine working well.

Image Source: pexels

A cnc router machine uses a computer to control how it cuts and shapes things. It can work with wood, plastic, and metal. The cnc router follows a digital plan to move its cutting tool very carefully. Many factories and shops use cnc routers to make furniture, signs, and car parts. The main parts of a cnc router are the spindle, worktable, control system, and tool changer. These parts help the router move well and cut things exactly right.

Cnc routers help companies make special furniture and cool designs fast. They can cut many things like wood, MDF, acrylic, and even aluminum. The machine checks itself to keep the cutting tool lined up with the plan. This makes sure every piece looks the same. People need to take care of the spindle and bearings so the router keeps working. Workers set up the material and tools to stop mistakes. Good cutting tools and smart software help the cnc router make smooth cuts and nice patterns.

Tip: Keeping the area clean and using dust collectors helps the cnc router work better and stops problems.

Lots of businesses use cnc routers because they are fast, accurate, and can do many jobs. For example:

Custom furniture makers use cnc routers for tricky designs and quick work.

Car part makers use cnc routers to cut many materials and save time.

Sign companies use cnc routers to make signs with lots of detail.

Cnc routers help cut down on waste and make things faster.

The industrial atc cnc router is even better because it changes tools by itself. This saves time and lets the machine work longer without stopping.

The atc cnc router is different from regular cnc routers because it can switch tools by itself. This makes it much faster and better at getting work done. The automatic tool changer uses a servo or air system to swap tools in less than three seconds. A regular cnc router needs a person to change the tool, which can take up to two minutes. This means the atc cnc router works over 90% faster and can run all day.

Here is a table that shows the main differences:

| Performance Aspect | ATC CNC Routers | Other CNC Routers | Key Differentiator |

|---|---|---|---|

| Tool Change System | Automatic (servo/pneumatic) | Manual | Tool change speed is 5-10 times faster |

| Tool Change Time | 0.8 to 3 seconds | 30 seconds to 2 minutes | Efficiency increased by over 90% |

| Production Continuity | Supports 24-hour continuous production | Depends on manual intervention | Productivity increased by 2-3 times |

| Tool Capacity | 6 to 24 tools (expandable) | Only 1 tool (manual replacement) | Supports multi-tool automatic switching |

The atc cnc router uses smart control systems like Syntec or Siemens and strong spindles. It can work with many materials like wood, plastic, leather, stone, and metal. The multi head cnc router uses more than one spindle to work on different parts at once. It is mostly used to make furniture like cabinets and doors. The multi head cnc router changes tools by moving an outside cylinder and switching spindles. This takes longer and can make the cuts less exact.

| Feature | ATC CNC Router | Multi Head CNC Router |

|---|---|---|

| Tool Change Mechanism | Uses internal cylinder movement to change tools quickly without stopping work | Changes cutters by moving external cylinder and switching spindles |

| Control Systems | Syntec, Siemens, Italy HSD ATC spindle, HQD spindle, Siemens servo motor, etc. | LNC, Syntec, DSP control systems, Dongling servo motor, HQD spindle, etc. |

| Price Range | Approximately $10,000 to $35,000 | Approximately $8,000 to $15,000 |

| Processing Precision | High precision | Lower precision compared to ATC CNC router |

| Processing Range | Wide applications: furniture, advertising, musical instruments, foam molding, crafts, etc. | Mainly furniture making: cabinets, doors, beds, wardrobes |

| Materials Processed | Wood, plywood, MDF, acrylic, plastic, leather, stone, aluminum, brass, foam, fabric | Mainly wooden materials: solid wood, artificial wood, plywood, MDF |

| Processing Effects | Cutting, engraving, drilling, milling, punching, grooving, boring | Cutting, engraving, drilling |

Both the atc cnc router and the multi head cnc router use similar software and look a lot alike. But the atc cnc router is faster and more exact because it does not need people to change tools. The industrial atc cnc router can do more jobs and is good for many kinds of work. The multi head cnc router is best for simple furniture jobs.

The main parts of a cnc router, like the automatic tool changer, strong spindle, and smart control system, help the atc cnc router do a better job. The auto tool changer and strong hold-down system keep the machine working well and cutting right. The industrial atc cnc router also uses auto oiling and dust collectors to keep things clean and working right.

The atc cnc router gives companies a great way to work fast, make things right, and do many jobs. It is the best pick for businesses that want good results and to get work done quickly.

Image Source: pexels

Knowing about automatic tool changer technology helps people understand why cnc router machines are so good. The automatic tool changer is a smart part that lets the cnc router swap tools without stopping. This system has a disc or carousel that holds many tools. When the cnc router needs a new tool, the automatic tool changer puts the right tool in place. This happens fast and does not need help from a person.

The Zhongyuan 1325 ATC CNC Wood Router Machine uses a disc tool changer. The disc can hold up to 12 tools at once. The router can pick any tool from the disc in just a few seconds. Because of this, the cnc router can do jobs like drilling, cutting, and engraving without stopping for someone to change tools. Many studies show that using an automatic tool changer in a cnc router makes work faster, needs less labor, and makes each job more exact.

How does a cnc router work with an automatic tool changer? First, the cnc router gets a command from its control system. The router checks which tool it needs next. The automatic tool changer moves the right tool from the disc to the spindle. The router locks the tool in place and starts working right away. This tool change only takes a few seconds.

The automatic tool changer works with the cnc router for smooth operation. The router does not have to stop or wait for someone to change tools. This setup makes work faster and keeps production going. Studies show that factories using automatic tool changers finish jobs quicker and make better products. Using an automatic tool changer means less waiting, fewer mistakes, and more finished work.

Note: Many studies and reviews agree that automatic tool changers in cnc routers help companies save time, lower costs, and work more efficiently. This technology helps meet the need for more automation in today’s factories.

A multi head cnc router uses several spindles to work on different parts at the same time, but the automatic tool changer gives even more options. The router can switch between many tools for hard jobs. This makes the cnc router a great choice for businesses that want to work faster and make better products.

The Zhongyuan 1325 ATC CNC Wood Router Machine with Disc Tool Changer is special in woodworking. This cnc router has an air-cooled spindle. The spindle helps the machine run for a long time. It does not get too hot. Many people say air-cooled spindles keep cuts smooth and steady. The machine also has a vacuum adsorption table. This table holds wood and other things tight. The double-layer holes help stop the router from slipping.

A strong steel bed gives the cnc router good support. The thick frame keeps the bed from bending. This is true even when jobs are hard. Experts say a solid bed helps the router stay exact and last longer. The machine has a dust suction port that works well. This part takes away dust and chips while the router cuts. A clean area helps the cnc router stay accurate and safe.

The control system is Taiwan Baoyuan MW2200. This system helps the router follow commands fast and right. The tool magazine can hold up to 12 tools. This lets the router change tools quickly. The electric oil system keeps moving parts smooth. The router adds oil by itself. Workers do not need to stop the machine.

Tip: The multi head cnc router can do many jobs at once. But the ATC system in this router makes tool changes much faster and easier.

The cnc router gives higher precision for every job. The fast transmission system lets the router move quickly and stay exact. The machine can cut, drill, and engrave with fine detail. Many factories use this cnc router for furniture, cabinets, doors, and custom work. The router is good for both easy and hard designs.

The multi head cnc router is good for making many parts at once. The ATC cnc router gives better precision and faster tool changes. The vacuum table and strong bed help each cut stay exact. The dust system keeps the router clean. This helps the cnc router last longer. The easy controls make it simple for workers to learn and use.

The multi head cnc router, the ATC cnc router, and the cnc router machine are all important in woodworking today. The Zhongyuan 1325 model brings speed, power, and high precision for great results.

The furniture industry uses the atc cnc router for many jobs. Companies use this machine to make things like cabinets and desks. It helps workers carve details and make smooth edges. Many factories use the 1325 ATC CNC Wood Router Machine for cutting and drilling wood. This cnc router can handle easy and hard shapes. This gives companies more ways to make special designs.

Most cnc routers are used for woodworking. These machines help make furniture and decorations. The cnc router works fast and cuts very exactly. Many companies pick cnc routers to make unique furniture. More people want custom furniture now. Cnc routers help meet this need.

CNC routers help make fancy furniture, doors, and moldings.

More online shopping means more people want custom furniture. Cnc routers make these pieces quickly.

More automation, better accuracy, and faster work are big reasons companies use cnc routers.

The global market for woodworking cnc routers is growing. More companies use these machines to make furniture. The industrial atc cnc router helps with both old and new furniture styles.

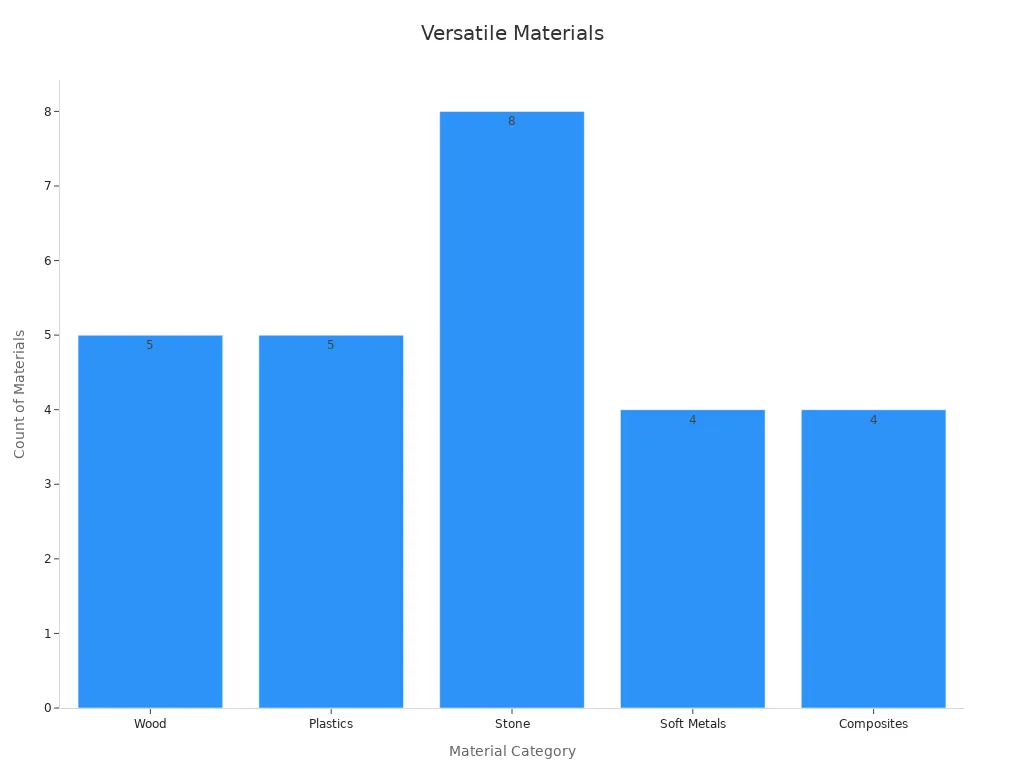

The atc cnc router can work with more than just wood. It can cut plastics, aluminum, foam, and stone. This makes the cnc router useful in many jobs. It is used in advertising, mold making, and making tools. The machine can change tools fast. This helps with drilling, cutting, and engraving.

| Material Category | Examples of Materials Processed | Application Examples |

|---|---|---|

| Wood | Plywood, Soft Wood, Hard Wood, MDF, Chipboard | Woodworking, furniture making |

| Plastics | Acrylic, ABS, HDPE, PVC, UHMW | Sign making, advertising, mold making |

| Stone | Granite, Marble, Slate, Basalt, Pebbles, Natural Stone, Ceramic, Porcelain | 3D stone carving, statues |

| Soft Metals | Aluminum, Brass, Copper, Mild Steel | Mold making, industrial manufacturing |

| Composites | Aluminum Composite, Copper Composite, Titanium Composite, Zinc Composite | Aerospace, precision instrument shells |

CNC routers with automatic tool changers can do many jobs without stopping. They can do more than one thing at a time and make fewer mistakes. Common uses for an atc cnc router are sign making, logo cutting, and making sculptures. The cnc router is flexible and very exact. This makes it a good pick for woodworking and factories.

Note: The atc cnc router is great because it can do many jobs. It works well for furniture, ads, and detailed carving.

The cnc router helps businesses finish work faster and better. The many uses of an atc cnc router show how helpful it is in lots of jobs.

Picking a cnc router for your shop takes some thought. Experts say you should first think about what you will use it for. Some people want a cnc router for woodworking. Others need it for plastics or metal. What you plan to make decides what features you need. The materials you use are important. A cnc router with a strong spindle and tough frame is better for hard stuff. The size of the machine matters too. Big projects need a bigger table and more Z-axis space.

The right cnc router for your job makes work faster. Features like automatic tool changers and vacuum tables help you do more. How much money you have is also important. Cheaper cnc routers have fewer features. Industrial ones cost more but can do more work. It is smart to pick a supplier who gives good help and support.

| Decision Factor | Why It Matters for Processing Efficiency |

|---|---|

| Intended Use | Makes sure the cnc router fits your needs |

| Material Compatibility | Matches the spindle and tools to your material |

| Size and Capacity | Lets you work on big or small jobs |

| Accuracy & Features | Helps you work better and faster |

| Budget | Balances what you pay with what you get |

| Supplier Support | Helps your machine last and work well |

To pick the best atc cnc router, look at the axis setup, tool magazine, and software. The Zhongyuan 1325 ATC CNC Wood Router Machine has a big work area, strong spindle, and easy controls. These things help you work faster in your shop.

Taking care of your cnc router helps it last longer. Many people want to know how to keep a cnc router with a tool changer working well. You should oil the moving parts often so they do not wear out. The Zhongyuan 1325 model has an electric oil system that makes this easy. Keeping dust away is also important. A good dust suction port keeps the area clean and safe.

Good support from your supplier helps fix problems fast. The best suppliers give you spare parts, updates, and help online. This keeps your cnc router working and stops long breaks in work. Learning how to care for your cnc router with a tool changer helps it last longer and keeps your shop running.

Picking an atc cnc router that is easy to care for and comes with good support helps your business. The Zhongyuan 1325 ATC CNC Wood Router Machine gives you these things. It is a smart pick for people who want to work fast and make good products.

An ATC CNC router can change tools by itself very fast. This helps work get done quicker and with better accuracy. The cnc router lets factories and shops do more jobs with less effort. It makes things easier and helps them work better. The Zhongyuan 1325 ATC CNC Wood Router Machine is great for making furniture and woodworking. Experts think cnc router technology will keep getting better. There will be more automation and smart features in the future. Training programs like SACA and Tooling U-SME teach people how to use cnc routers. People should think about what they need and how to take care of the machine before buying a cnc router.

| Certification Program | Key Features | User Benefits | Cost Range |

|---|---|---|---|

| SACA CNC Certification | CNC programming, IoT, predictive maintenance | Reduces training time, bridges automation skills | $100–$1,500 |

| Tooling U-SME CNC Certification | Basic to advanced CNC, automation | Upskills operators, flexible learning | $150–$5,000 |

ATC means Automatic Tool Changer. This system lets the CNC router pick tools by itself. People do not need to change tools by hand. The machine works faster and saves time.

The Zhongyuan 1325 ATC CNC Wood Router can hold 12 tools in its disc tool changer. This helps the machine do many jobs like cutting, drilling, and engraving. It does not need to stop for someone to change tools.

Yes, the ATC CNC router can work with plastics, aluminum, foam, and some stone. This makes the machine good for many jobs. It is used in furniture, ads, and mold making.

The vacuum adsorption table keeps the material tight and still. This stops it from moving when the machine cuts or engraves. The router can make smoother and more exact cuts.

Tip: Clean the vacuum table often. This keeps the suction strong and helps you get better results.