Views: 0 Author: Site Editor Publish Time: 2025-06-27 Origin: Site

You see CNC machines at work in a wide range of industries, including aerospace, automotive, medical devices, electronics, and woodworking. CNC machining drives precision and efficiency in manufacturing, supporting everything from aircraft frames to custom furniture. The global CNC market has reached around USD 90.5 billion in 2024, with the Asia-Pacific region accounting for about 39% of that share.

You see CNC machines at work in a wide range of industries, including aerospace, automotive, medical devices, electronics, and woodworking. CNC machining drives precision and efficiency in manufacturing, supporting everything from aircraft frames to custom furniture. The global CNC market has reached around USD 90.5 billion in 2024, with the Asia-Pacific region accounting for about 39% of that share.

Shandong Zhongyuan Machinery Co., Ltd. stands out in woodworking and furniture manufacturing, offering advanced CNC machinery for seamless production.

| Industry | Key CNC Applications |

|---|---|

| Aerospace | Frames, engine parts, landing gear |

| Automotive | Engine blocks, transmissions, suspension systems |

| Woodworking | Furniture, cabinetry, custom wood components |

CNC machines improve precision and speed in many industries like aerospace, automotive, medical, electronics, and woodworking.

They help produce complex parts with tight tolerances, reducing errors and waste while boosting efficiency and safety.

CNC technology supports both mass production and custom projects, allowing quick changes and fast prototyping.

Automation with CNC machines lowers costs, improves quality, and reduces workplace injuries by limiting manual work.

Companies like Shandong Zhongyuan Machinery Co., Ltd. provide advanced CNC solutions that enhance woodworking and furniture manufacturing.

You see the aerospace industry rely on CNC machining for the production of high precision components. Aircraft manufacturers use 5-axis CNC mills to create complex parts such as engine components, landing gear, and structural frames. These machines handle titanium, aluminum, and composite materials, ensuring each part meets strict safety and performance standards.

The applications of cnc machining in aerospace demand repeatability and precision. Even a small deviation can compromise the safety of an entire aircraft. You benefit from the cnc machining process because it delivers consistent quality and allows for the creation of customized parts for different aircraft models.

A documented dataset from industrial production shows that 5-axis CNC machines can record manufacturing data at one-second intervals, supporting the need for traceability and process optimization in aerospace manufacturing.

In the automotive industry, cnc machining services play a vital role in producing engine blocks, cylinder heads, transmission gears, and suspension systems. You depend on cnc machines to achieve tolerances as tight as ±0.01 mm, which is essential for performance and safety.

CNC machining applications in automotive include:

Engine blocks and cylinder heads

Transmission gears and shafts

Suspension arms and brackets

Custom prototypes for new vehicle models

CNC machines enable you to manufacture complex geometries quickly and efficiently. Automation and optimized toolpaths reduce material waste and manual labor, leading to faster production and cost savings. You can reprogram cnc machines rapidly, which supports both prototyping and small production runs. This flexibility helps you bring new designs to market faster and maintain consistent quality across all parts.

The medical industry depends on cnc machining services to produce precise parts for implants, surgical instruments, and diagnostic equipment. You require micron-level tolerances for orthopedic implants and dental devices, which only cnc machines can deliver.

CNC machining applications in the medical industry include:

Orthopedic implants (hip and knee replacements)

Surgical instruments (scalpels, forceps, clamps)

Dental implants and prosthetics

Custom surgical guides

CNC machining process in the medical industry demonstrates exceptional reliability, with error rates below 0.005%. This high precision ensures that medical devices meet strict regulatory standards like ISO 13485. You benefit from rigorous quality control, including dimensional analysis, material traceability, and comprehensive documentation. These practices improve patient outcomes by reducing device malfunctions and post-operative complications.

Reliable cnc machining services use calibrated measurement tools and continuous improvement methods, such as Lean and Six Sigma, to maintain process stability and reduce defects.

You find cnc machining essential in the electronics industry for manufacturing enclosures, connectors, heat sinks, and circuit board housings. The applications of cnc machining in electronics require both high precision and repeatability.

CNC machines produce:

Aluminum and plastic enclosures for electronic devices

Precision connectors and sockets

Custom heat sinks for thermal management

Mounting brackets and chassis components

Precision in cnc machining means cutting each part exactly to the intended dimension, such as 50 mm, every time. Repeatability ensures that you get the same result in every production run, which is critical for electronic components that must fit together perfectly. Factors like machine calibration, environmental control, and operator expertise all affect the outcome.

Measurement System Analysis and Gauge Repeatability and Reproducibility studies help you identify and minimize sources of variation, ensuring that your cnc machining services deliver consistent, high-quality results.

In electronics, even a minor error can cause device failure, so you rely on cnc machines for their ability to maintain tight tolerances and produce precise parts at scale.

CNC machines have transformed the manufacturing industry. You see their impact in sectors like tool and die, construction, military, energy, and food and beverage. These machines deliver unmatched precision, speed, and consistency. The applications of cnc machining in these fields help you achieve higher quality, lower costs, and safer workplaces.

You rely on cnc machines for tool and die production. These machines shape molds, dies, and specialized tools with tight tolerances. CNC machining services let you create complex forms that manual methods cannot match. You benefit from reduced errors, faster turnaround, and consistent results. The applications of cnc machining in tool making include stamping dies, injection molds, and cutting tools.

Here’s how cnc machines impact manufacturing performance:

| Aspect | Evidence Summary |

|---|---|

| Economic Impact | CNC global market size was $80 billion in 2019, projected to reach $115 billion by 2026, showing growing adoption and investment. |

| Error Reduction | CNC automation reduces production errors to nearly zero, minimizing waste and lowering operating costs. |

| Efficiency and Speed | CNC machines operate continuously without fatigue, enabling rapid prototyping and faster production cycles. |

| Waste Reduction | CNC machining uses materials more efficiently, reducing waste compared to traditional methods. |

| Safety Improvements | Automation reduces human interaction with hazardous processes, lowering workplace injury risks. |

| Quality and Precision | CNC technology improves product accuracy and allows manufacturing of complex, precise parts. |

| Operating Costs | Reduced need for manual labor and fewer errors lead to lower overall operating costs. |

You see these benefits every day in the tool and die industry. CNC machines help you meet strict deadlines and deliver reliable products.

In construction, cnc machines play a key role in fabricating building components. You use cnc machining to cut steel beams, drill holes in concrete panels, and shape custom metal parts. The applications of cnc machining in construction include producing window frames, staircases, and decorative elements. CNC machining services give you the flexibility to handle both large-scale and custom projects.

CNC machines operate around the clock. You get faster project completion and improved safety. Automation reduces the risk of injury by limiting manual handling of heavy materials. You also see less waste, as cnc machines cut materials with high accuracy.

You depend on cnc machines for military manufacturing. The industry demands parts with extreme precision and reliability. CNC machining services produce components for aircraft, vehicles, naval vessels, and advanced weaponry. You need exact repeatability and robust machine design to meet military standards.

Key military applications for cnc machining include:

Aircraft components with tight tolerances

Firearm parts and assemblies

Naval vessel propulsion and weapons systems

Communication and surveillance equipment such as drones and radar systems

You see leading defense companies use 5-axis cnc machines for complex aerospace parts. For example, Lockheed Martin and Northrop Grumman use cnc machining to create F-35 and B-2 bomber components. These machines finish work in a fraction of the time compared to older methods. You benefit from high consistency, fast turnaround, and the ability to customize parts for new military technologies.

CNC machines drive innovation in the energy industry. You use cnc machining to manufacture turbine blades, pump housings, and valve components. These machines handle tough materials like stainless steel and titanium. CNC machining services help you achieve high part quality and low rejection rates.

You measure cnc machine efficiency using several metrics:

Cutting speed and feed rate

Material removal rate

Tool wear and tool life

Rejection rate and part quality rate

Overall equipment efficiency (OEE)

Power or energy consumption

Cost per part

You also use sensors to monitor temperature, vibration, and pressure. CAM software helps you optimize machining processes. Robotics and automation reduce delays and improve consistency. Artificial intelligence predicts maintenance needs, so you avoid unexpected downtime.

You see cnc machines in food and beverage manufacturing, especially for equipment parts. CNC machining creates stainless steel fittings, valves, and conveyor components. You need smooth surfaces and precise dimensions to meet hygiene standards.

| Improvement Aspect | Quantitative Improvement | Description |

|---|---|---|

| Machinery Component Lifespan | 30% increase | High-speed machining and advanced coolant management extended the lifespan of stainless steel parts in beverage bottling machinery. |

| Scrap Rate Reduction | 5% reduction | Routine calibration of CNC machines reduced scrap rates and improved consistency in stainless steel fittings for food processing lines. |

| Surface Finish Quality | Indirect quantitative impact | Enhanced surface finish via CNC machining and electropolishing improved hygiene and cleaning efficiency by reducing residue buildup in dairy equipment. |

You benefit from longer-lasting equipment and lower scrap rates. CNC machines help you maintain strict quality control and meet industry regulations. The applications of cnc machining in this sector support safer, cleaner, and more efficient production lines.

You see cnc machines transform furniture manufacturing by delivering unmatched speed, precision, and consistency. In modern factories, cnc routers handle cutting, engraving, drilling, and milling tasks with high accuracy. You can automate material handling and labeling with advanced models, which boosts efficiency and reduces manual labor. Edge banding machines finish furniture edges, improving both appearance and durability. With these technologies, you manage multiple machines at once, saving time and lowering costs.

cnc technology supports mass production and customization.

cnc routers increase processing speed and accuracy for furniture and cabinets.

Edge banding machines seal edges, reduce emissions, and enhance product quality.

Automation lets you meet tight deadlines and maintain high standards.

When you work on custom woodworking projects, cnc machines give you the flexibility to create detailed designs and prototypes. You achieve complex carvings and shapes that would be difficult with traditional tools. Advanced software lets you generate toolpaths for intricate patterns, while machine options fit projects of any size.

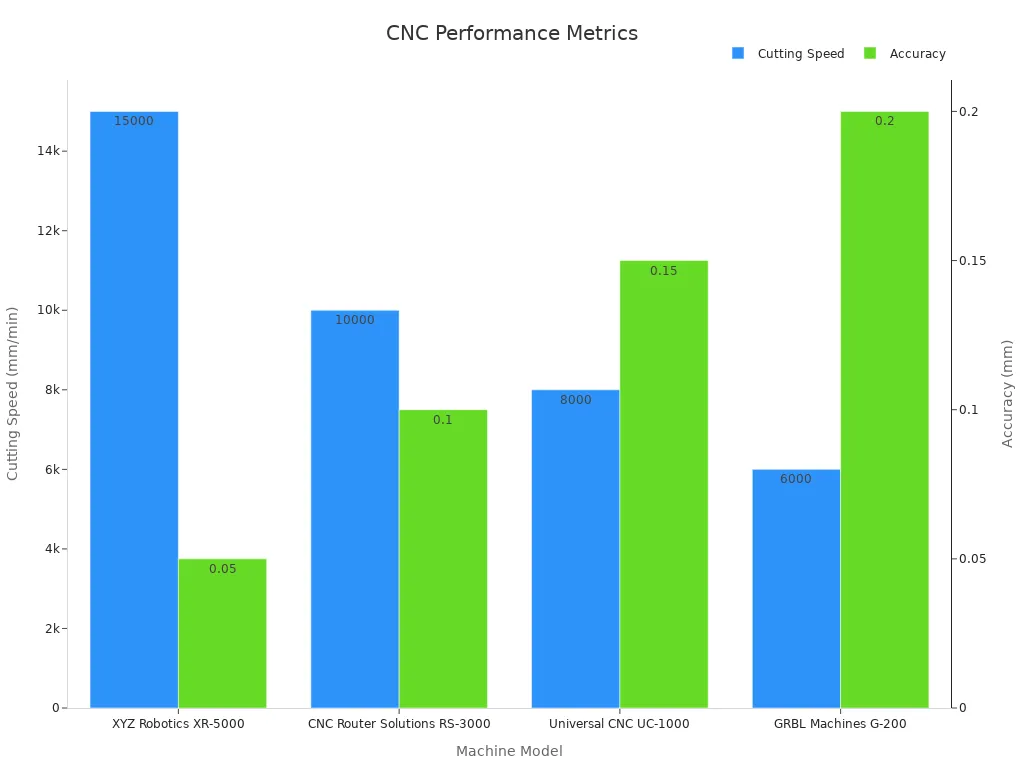

Here’s how different cnc machines compare for custom woodworking:

| Machine Model | Max Cutting Speed (mm/min) | Accuracy (mm) | Work Area Dimensions (mm) |

|---|---|---|---|

| XYZ Robotics XR-5000 | 15000 | ±0.05 | X: 1000, Y: 600, Z: 300 |

| CNC Router Solutions RS-3000 | 10000 | ±0.1 | X: 800, Y: 500, Z: 200 |

| Universal CNC UC-1000 | 8000 | ±0.15 | X: 600, Y: 400, Z: 150 |

| GRBL Machines G-200 | 6000 | ±0.2 | X: 500, Y: 300, Z: 100 |

You benefit from higher accuracy, faster production, and the ability to handle unique requests. cnc technology reduces errors and ensures every piece meets your specifications.

You find Shandong Zhongyuan Machinery Co., Ltd. at the forefront of cnc machinery for woodworking. The company designs and manufactures advanced cnc routers, edge banding machines, and drilling machines for furniture and custom wood production. Their cnc machinery lineup includes automatic edge banding machines, curve edge banding machines, and multi-axis cnc routers.

You can customize machines to fit your production needs.

Automation and integration with MES or ERP systems optimize your workflow.

The company’s solutions help you save space, improve efficiency, and deliver consistent quality.

With Shandong Zhongyuan Machinery Co., Ltd., you gain a trusted partner for modern woodworking. Their cnc technology supports both large-scale manufacturing and specialized custom projects, helping you stay competitive in a fast-changing industry.

You see cnc machines play a vital role in the marine industry. Shipbuilders use cnc machinery to create water-resistant and corrosion-resistant components. These machines help you produce custom keels, propellers, and hull fittings that withstand harsh, wet environments.

CNC machines deliver high precision in keel fabrication, which improves hydrodynamic efficiency and vessel performance. You can design complex geometries for keels and propellers, giving each vessel a unique advantage on the water.

| Sector | CNC Machining Benefits | Measurable Improvements / Outcomes |

|---|---|---|

| Marine | Custom, water-resistant, corrosion-resistant, durable parts | Enhanced longevity and performance in harsh, wet environments; reduced wear and damage; custom fit for vessels |

You benefit from reduced production time and material waste. Automation ensures every part meets exact specifications. Leading shipyards, such as Royal Huisman, use cnc machines to fabricate lightweight, precise keels for superyachts, balancing strength and aesthetics.

In agriculture, cnc machines help you manufacture durable equipment and machinery parts. You rely on cnc machinery to produce tractor components, irrigation system parts, and harvesting tools. These machines allow you to create customized parts that fit specific models or unique farming needs.

You can quickly replace worn-out parts with new, precise components.

CNC machines improve the reliability and lifespan of agricultural equipment.

You reduce downtime during planting and harvesting seasons.

You see cnc machinery support innovation in smart farming. Farmers use cnc machines to develop advanced prototypes for automated systems, such as robotic planters and precision sprayers. This technology helps you boost productivity and adapt to changing agricultural demands.

You depend on cnc machines for rapid prototyping across many industries. When you need to test new ideas, cnc machinery lets you create accurate prototypes quickly.

You can produce up to ten prototypes in a single day, speeding up product development.

CNC machines allow you to test different materials and designs before full-scale production.

You use prototypes to check fit, function, and appearance, reducing costly mistakes.

With cnc machines, you can make customized parts for each prototype, ensuring every version meets your requirements. Rapid prototyping helps you bring products to market faster and respond to customer feedback with agility.

CNC machines open new possibilities in art and design. You use cnc machinery to create kinetic sculptures, interactive installations, and custom furniture. Artists and designers rely on cnc machines to achieve intricate details and complex shapes that traditional tools cannot match.

You can integrate sensors, motors, and electronics into cnc-machined parts for interactive artworks.

Advanced techniques, such as multi-axis machining, let you produce dynamic motion and unique textures.

CNC machines help you create prototypes for new art pieces, allowing for experimentation and refinement.

You benefit from improved precision, repeatability, and material versatility. CNC machines enable you to push creative boundaries and deliver customized parts for every project.

You see cnc technology shaping industries worldwide, from aerospace to woodworking. Manufacturers report a 22% reduction in production time and a 15% decrease in material waste by adopting advanced cnc technology.

The cnc milling machine tools market is projected to reach $111.94 billion by 2032.

Automation and IoT integration continue to drive efficiency and innovation.

Companies like Shandong Zhongyuan Machinery Co., Ltd. lead the way, helping you meet modern demands with reliable, cutting-edge solutions.

You can process metals, plastics, wood, composites, and foam with a CNC machine. Each material requires specific tooling and machine settings. CNC technology adapts to a wide range of manufacturing needs.

CNC machining delivers high precision and repeatability. You achieve consistent part dimensions and smooth finishes. Automated controls reduce human error and maintain strict quality standards.

Yes, you can. CNC machines allow quick reprogramming for new designs. You can produce prototypes, custom parts, or small batches efficiently without expensive tooling changes.

You see the greatest benefits in aerospace, automotive, medical devices, woodworking, and electronics. These industries require tight tolerances, complex shapes, and reliable production.

You gain access to advanced CNC routers, edge banding machines, and custom solutions. The company offers strong after-sales support and innovative technology for efficient, precise woodworking production.